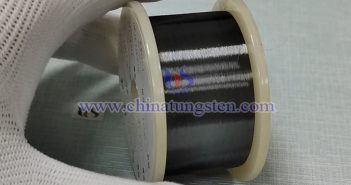

The core design of tungsten wire heating elements used in glass heating equipment (such as glass kilns, furnaces or vacuum coating equipment) is to use the extreme high temperature stability and efficient radiation heat transfer ability of tungsten metal to achieve uniform and rapid heating of glass in harsh environments. The following are its key design principles: I. Material Selection: Excellent High Temperature Performance of Tungsten 1. Ultra-High Melting Point: This is the cornerstone of tungsten wire design. Glass processing…