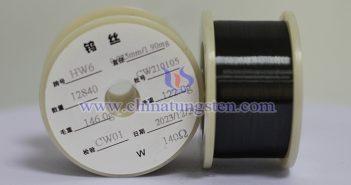

The packaging of tungsten wire for glass heating usually needs to consider factors such as high temperature tolerance, oxidation resistance, moisture resistance, and transportation safety. The following are some common packaging methods and precautions: 1. Vacuum Packaging: Tungsten wire is easy to oxidize at high temperatures, so vacuum sealed packaging (such as vacuum plastic bags or vacuum aluminum foil bags) is often used to isolate the air and prevent oxidation and moisture intrusion. This packaging can effectively extend the shelf…