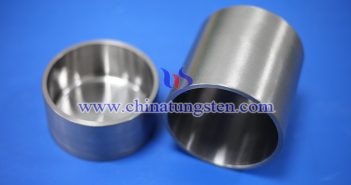

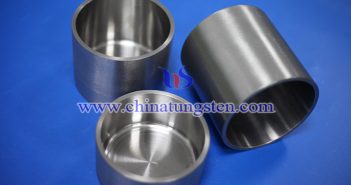

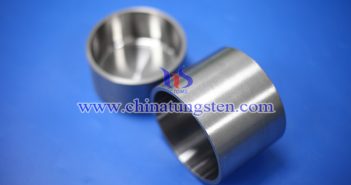

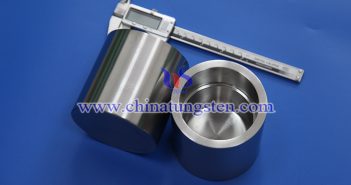

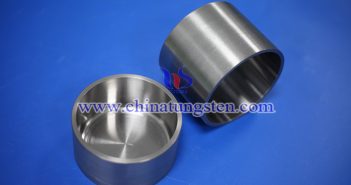

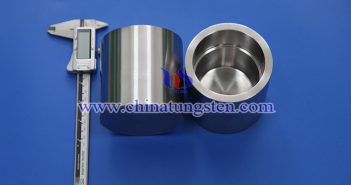

As a basic material in the semiconductor industry and photovoltaic field, the quality of monocrystalline silicon directly determines the performance and efficiency of downstream products. As an important high-temperature container in the monocrystalline silicon growth furnace, tungsten crucible plays the role of bearing and heat transfer of molten silicon, and its performance has a decisive impact on the stability and crystal quality of the crystal growth process. However, its application faces a number of key technical challenges, which require in-depth…