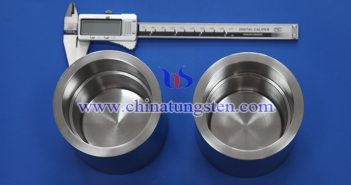

Tungsten crucibles play an important role in high-temperature metallurgy, crystal growth, vacuum smelting and other fields, and have long been known for their excellent high temperature resistance and good chemical stability. However, with the increasing complexity of the application environment, more and more users have begun to pay attention to its wear resistance. Abrasion resistance, as an index to measure the ability of materials to resist surface damage under mechanical actions such as friction, impact, and grinding, is a performance…