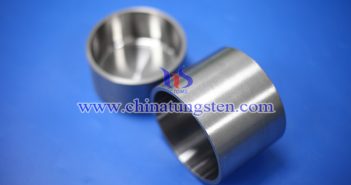

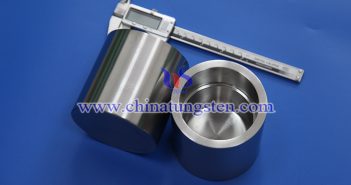

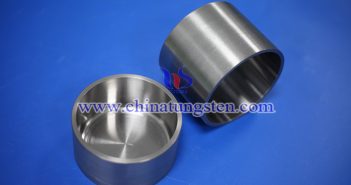

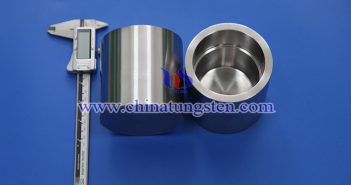

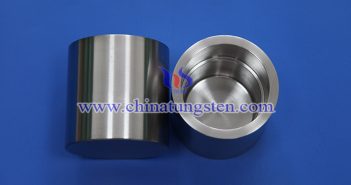

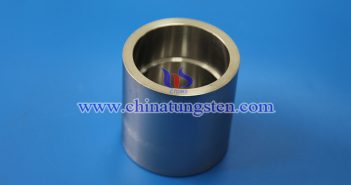

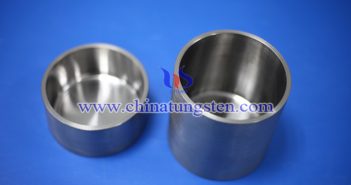

Tungsten crucibles are widely used in crystal growth, metal smelting and vacuum evaporation processes. However, in the high-temperature oxidation environment, its performance has certain particularities and limitations, which has become an important issue that must be paid attention to in its practical application. In air or oxygenated atmosphere, when the temperature exceeds 400°C, the tungsten surface begins to oxidize to form tungsten trioxide (WO?). As the temperature rises further, this oxide gradually forms a brittle oxide film on the surface…