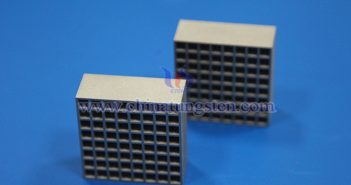

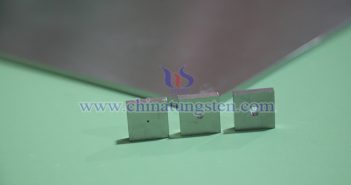

Tungsten contacts are electrical contact materials primarily composed of refractory metal tungsten and other metal elements such as copper or silver, exhibiting excellent thermal, mechanical, and electrical properties, and are widely used in the power sector. Based on their chemical composition, they can be classified into tungsten-copper (WCu) contacts and silver-tungsten (AgW) contacts. Conceptually, AgW contacts are materials composed of silver and tungsten, forming a two-phase pseudo-alloy with tungsten as the hard phase and silver as the binding phase, known…