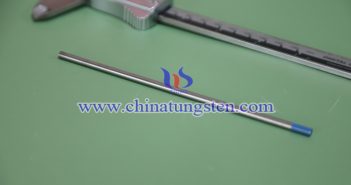

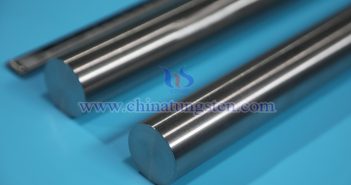

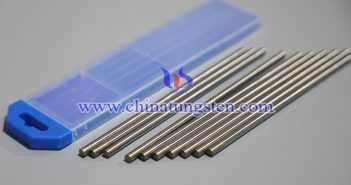

In modern welding technology, the choice of electrode material directly impacts welding quality, efficiency, and equipment stability. As a key consumable widely used in TIG (tungsten inert gas arc welding) and plasma cutting, tungsten electrodes, due to their high melting point, excellent conductivity, and ablation resistance, have become a vital component in industrial manufacturing. In recent years, with increasing demands for environmental protection and welding performance, electrode materials doped with rare earth elements (such as lanthanum) have gradually replaced traditional…