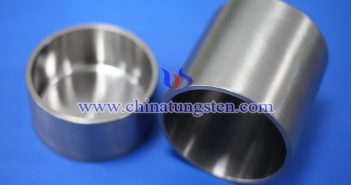

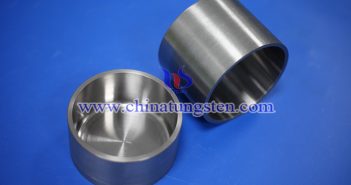

In the field of advanced materials, tungsten niobium alloy, a typical refractory metal composite, is gaining prominence as a critical foundational material in strategic sectors such as aerospace and high-end equipment manufacturing. This two-phase alloy system, composed of tungsten and niobium, achieves a complementary balance of tungsten’s high melting point and strength with niobium’s excellent ductility and corrosion resistance through elemental ratio control and microstructural design. Known as Tungsten Niobium Alloy or Niobium Tungsten Alloy, it demonstrates irreplaceable value in…