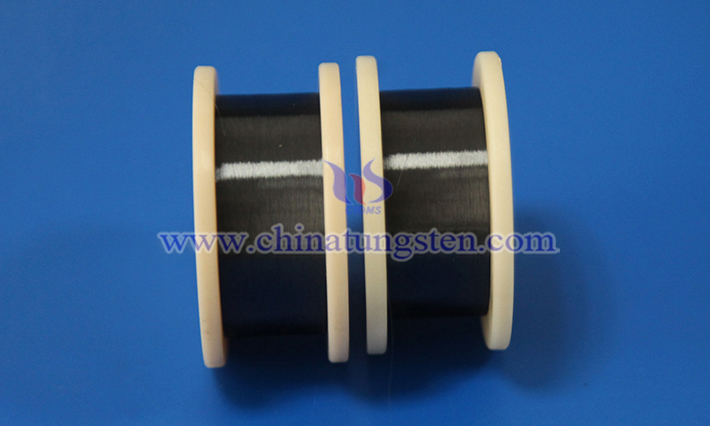

Anti-fog glass usually prevents fog condensation by embedding or coating a conductive material (such as tungsten wire or conductive film) on the glass surface and heating it with electricity. Tungsten wire is often used as a heating element in anti-fog glass systems that require heating, such as car rearview mirrors, bathroom mirrors or refrigerator glass doors, due to its high melting point, high resistivity, high temperature resistance and corrosion resistance.

1. Characteristics of Tungsten Wire

Tungsten wire has a high melting point (3422°C) and can work stably at high temperatures without melting or deformation. Its high resistivity (5.3×10?? Ω·m) makes it suitable as a resistive heating material and can generate heat quickly. In addition, tungsten wire is corrosion-resistant and suitable for humid environments, such as bathrooms or refrigerators. Doped tungsten wire (adding a small amount of potassium oxide, silicon or aluminum) can improve anti-sagging and high-temperature stability, while tungsten-rhenium wire (containing 3-5% rhenium) enhances shock resistance and ductility. Tungsten wire is made by powder metallurgy, hot forging and wire drawing, and its diameter can reach several microns, meeting the delicate needs of anti-fog glass.

2. Role of Tungsten Wire in Anti-Fog Glass

In anti-fog glass, tungsten wire is embedded in the glass interlayer or arranged on the surface as a heating element. It generates heat by powering on, so that the glass temperature is higher than the dew point to prevent water vapor condensation. The high resistivity of tungsten wire ensures efficient heating, while its high temperature resistance ensures long-term use without failure. To avoid oxidation, thin tungsten wires are usually sealed and protected to extend their service life. Compared with transparent conductive films (such as indium tin oxide), tungsten wire is not easy to be invisible, but it is suitable for specific high-durability scenarios.

3. Application Scenarios of Tungsten Wire for Anti-Fog Glass

The application of tungsten wire in anti-fog glass is wide and diverse. In the automotive field, the rearview mirror and rear windshield use tungsten heating system, which can quickly defog and improve driving safety. In the home field, the anti-fog mirror in the bathroom is embedded with tungsten wire or conductive coating to keep the mirror clear and improve the user experience. In commercial scenarios, the glass door of the refrigerator is heated by tungsten wire to prevent condensation from affecting the display effect of the goods. In addition, tungsten wire is also used for anti-fog glass in industrial equipment, such as refrigerated display cabinets, to ensure transparency and functionality.