The main role of tungsten wire in electric heated glass windows is to act as a heating element. By using its high resistance and high temperature resistance, the glass windows are heated by the resistance heat generated when the current flows through the tungsten wire to meet the various functional requirements such as anti-fogging, defrosting and temperature regulation.

1. Anti-Fogging and Defrosting

The main role of tungsten wire in electric heated glass windows is to prevent the formation of fog and frost. In cold or humid environments, the surface of the glass is prone to condensation of water vapor due to temperature differences, affecting transparency. For example, in the rear window of a car or the porthole of an airplane, the tungsten wire heats up rapidly after being energized, making the surface temperature of the glass higher than the dew point, thereby effectively preventing the formation of fog or frost, ensuring a clear field of vision for the driver or pilot, and improving safety.

2. Temperature Regulation

Tungsten wire can achieve dynamic regulation of glass temperature by precisely controlling the current. The high resistance of tungsten wire enables it to generate heat quickly when powered, while its high melting point (about 3422°C) ensures that it can still work stably at high temperatures. By adjusting the current, the heating power can be precisely controlled to maintain the glass surface in a suitable temperature range to avoid overcooling or overheating. This is especially important in scenarios where constant temperature is required, such as laboratory observation windows or architectural glass in low-temperature environments.

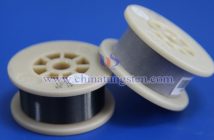

3. Structural Embedding

The application of tungsten wire in electrically heated glass windows is also reflected in its advantages in structural design. Usually, tungsten wire is embedded in the glass interlayer in the form of an extremely fine grid or film, which not only ensures uniform heat distribution, but also minimizes the impact on the light transmittance of the glass. This design ensures that the heating function coexists with the transparent and beautiful glass, meeting the needs of a variety of application scenarios. However, compared with indium oxide or silver-based conductive pastes, tungsten wire has a poor transparency advantage.