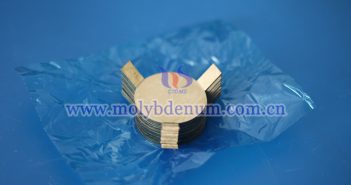

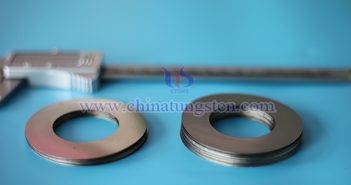

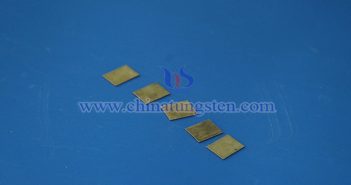

As a typical product of the transition metal molybdenum, molybdenum sheet is a sheet-like material processed from molybdenum metal through rolling, cutting, and other techniques. Beyond its use in electronics and aerospace for manufacturing high-temperature electronic components and sputtering targets, it is also employed to create heating elements in vacuum furnaces. Molybdenum sheet is an ideal material for vacuum furnace heating elements due to its multiple excellent properties: it has a high melting temperature, enabling stable operation in high-temperature environments;…