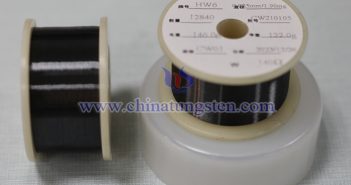

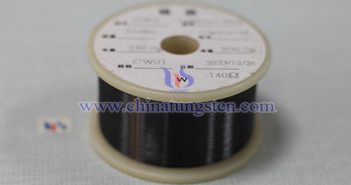

Pure tungsten wire or doped tungsten wire is usually preferred for glass heating because of its high melting point, high temperature resistance and excellent stability. It is necessary to select the appropriate tungsten wire specifications according to the glass type, heating temperature and equipment design, and ensure that vacuum or inert gas protection is used to extend the life. For more specific suggestions and purchases, please contact CTIA GROUP (sales@chinatungsten.com). 1. Why Choose Tungsten Wire? 1.1 High Melting Point: The…