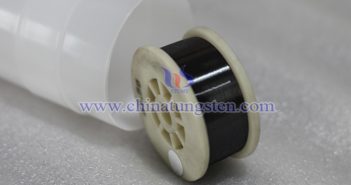

Due to its high melting point, high strength, and corrosion resistance, black tungsten wire has important applications in lighting, electronics, high-temperature industrial applications, medical treatment, welding, photovoltaics, and emerging fields. Although some traditional uses have been impacted by new technologies, its irreplaceable nature in high-temperature, high-precision applications ensures continued demand. 1. Lighting Industry Due to its high melting point and excellent electron emission properties, black tungsten wire is an ideal filament material for traditional incandescent and halogen lamps. Despite the…