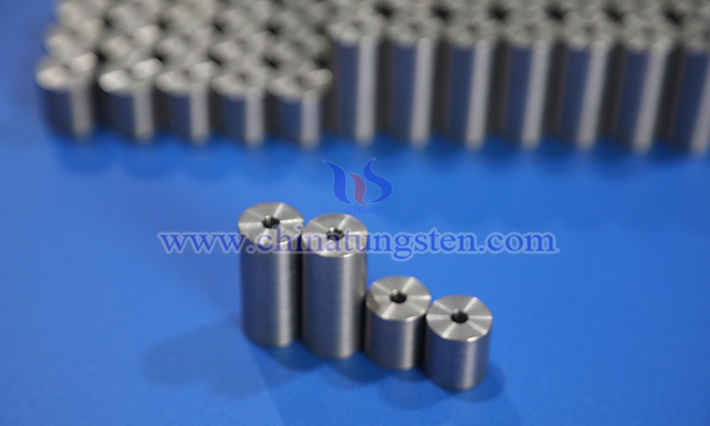

Tungsten alloy weights, made primarily from tungsten combined with other metal elements such as nickel and copper, are precision counterweights or measuring tools widely used in metrology and calibration fields.

The main characteristics of tungsten alloy weights include: High Density: At the same weight, its volume is smaller than that of ordinary weights. Excellent Mechanical Properties: Features high strength and hardness, resistant to wear, making it suitable for long-term use. Corrosion Resistance: Remains stable in various environments (e.g., moisture or chemicals), resisting rust or degradation. Environmental Friendliness: Non-toxic compared to lead, meeting modern environmental requirements. Processing Flexibility: Can be formed into complex shapes through various techniques to meet diverse design needs.

Tungsten-nickel-copper alloy weights exhibit significant performance differences compared to ordinary weights. With a density of 16.8–18.8 g/cm3, far exceeding that of steel (7.8 g/cm3) or lead (11.3 g/cm3), tungsten-nickel-copper alloy weights achieve the same weight in a smaller volume, while ordinary weights (e.g., stainless steel) are bulkier. Tungsten alloy weights achieve non-magnetic properties through a copper matrix and low nickel content, along with superior corrosion resistance, eliminating the need for additional anti-rust coatings; in contrast, ordinary steel weights are prone to magnetic interference, rust, and wear, requiring frequent calibration. In applications, tungsten-nickel-copper alloy weights, due to their high stability and non-magnetic nature, are widely used for calibrating precision balances, medical equipment, and scientific research; ordinary weights are typically used for routine weighing.

The primary application areas for tungsten alloy weights are in metrology and calibration: used to calibrate electronic balances, platform scales, truck scales, and other weighing equipment to ensure measurement results comply with national or international standards; employed in scientific laboratories and metrology institutions as reference or standard weights for high-precision mass comparison and testing; and utilized in industries like automotive and aerospace, where high accuracy in component quality is critical, for quality control inspections.